CNC Milling is the popularly used machining process that use the computer powered controls and rotating multiple point cutting tools to efficiently remove the materials from work piece and create some customized parts or products. This is the machining process which is suitable for machining a variety of materials including glass, plastic, wood and metal to produce a variety of customized parts and products.

There are a variety of capabilities that are being offered under the precision CNC Milling services and this includes electrical, chemical, mechanical as well as thermal processes. This is the robust mechanical machining process that involves turning, drilling, and other machining processes and this means that the materials for machining is removed from work piece using mechanical methods during the process for delivering custom made parts and products.

Brief Overview of CNC Milling Services

Like other traditional mechanical CNC Milling processes, it is the process that uses computer powered controls so as to operate and manoeuvre the machine tools that shape and cut the stock materials. It follows the same basic steps that all machining processes do including:

- Designing of the CAD model

- Converting of the CAD model into CNC program

- Setting the milling machine

- Execution of the milling operation

The milling process starts with generation of 2D and 3D part design and the completed design is then transferred to the CNC compatible file format and then it is finally converted by the CAM software program into the CNC machine that will further dictate the actions to the machine and movements of tooling across the work piece. Prior to starting the process, the operator always prepares the machine by attaching work pieces to the work surface of the machine.

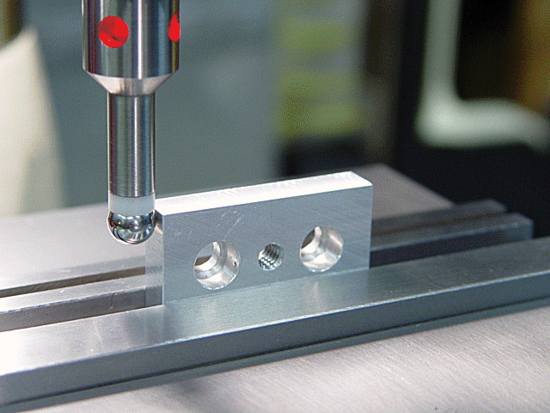

LED-edge-finder*

CNC Milling Operations

As mentioned, CNC Milling is the machining process that is the best option to produce high precision, tolerance parts in prototypes, small to medium production runs. With this milling process the parts are usually created with tolerances that range from +/- 0.001 in. to +/- 0.005 in. There are some models which can achieve the highest tolerances up to +/- 0.005 in. This milling process has the higher versatility capabilities that enable the machine to be used for a variety of applications and part features and designs including threads, chamfers, slots and pockets. Some of the most common types of its operations include:

- Plain milling

- Face milling

- Form milling

- Angular milling

- Gang milling

- Straddle milling

- Gear cutting

- Profile milling

- Other machining processes

What is the Significance of CNC Milling?

The digital technologies and the CNC Milling processes enable the industries to find many solutions to problems which are not possible using the age old traditional methods. This is the latest technology that approaches the working process in such a way that the end results are effective and efficient.

Today, it has been in use across varied industries to produce furniture, cabinets, woodworking, aluminium machining, instruments, sculptures, prototyping and modelling.

Reference

*Image from http://www.helmancnc.com/