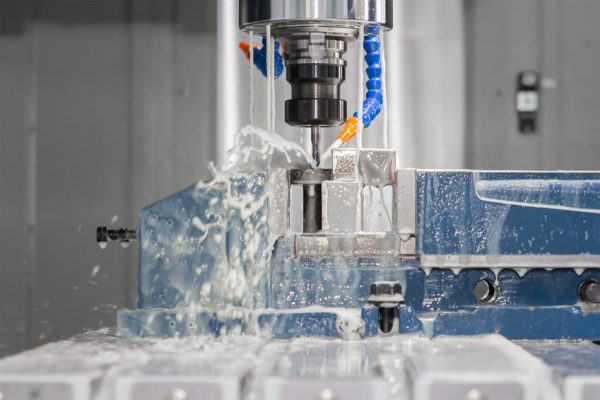

Material removal with the help of rotary cutters to obtain a product of the intended design, shape, and size is called milling. Paired with Computer Numeric Control, the manufacturing world obtained a process called CNC milling that led to increased sophistication and ease of production. It is the process of material removal from a block with the help of a machine that operates upon a set of instructions fed to the computer and thus the whole procedure is improved with automation.

Understanding CNC milling

Milling is carried out by the machine advancing a cutting part into the block that needs to be given the desired shape. It involves variations in the directions of one or more axes, speed of cutter head, and pressure applied by it. With CNC, cutting tools of all shapes from square, round, or angled can be easily used to create a wide range of assemblies and parts of varying geometries and shapes. The parts produced include engine parts, mould and custom tooling, enclosures or other machine parts of complicated mechanisms.

There are numerous kinds of technologies and machines that can be used including commonly used milling equipment, horizontally boring mills, and vertical milling centres.

CNC machining manufacturing*

The Different Types of Milling Machines

The ability to perform movements in different angles sets apart CNC milling machines from other CNC machines and that happens with the different number of axes in the machines. Based on the number of axes in the machines can be classified as follows:

2-axis milling machines

These machines can slots and holes in x- and z-axes, meaning they can move along either horizontally or vertically.

3-axis milling machines

The most popular type of machines, they can cut in x-, y-, and z-axes. Vertical and any other direction cutting is possible, but cutting from below is not. Thus, a sphere-like object will be done half at a time.

4-axis milling machines

Having similarity with a lathe, these machines have added advantage of rotation and it makes them more sophisticated.

5 axis milling machines

In these machines, rotation is possible in both x-, and y-axes. These can be used to build car models, medical equipment, aerospace structures, human or animal bones, or anything under the sun. These are the most advanced among machines classified as per the number of axes.

Apart from these, there are several other kinds of CNC milling machines that are put to uses for different purposes. For instance, a vertical mill has a table below the arm and is the work surface that can move up and down. Likewise, in a horizontal mill, only the spindle is kept vertical and thus it’s capable of rotating around the z-axis. A knee mill comes with an adjustable knee for easy movement of the table upwards and downwards.

All these kinds have varying benefits of their own, but CNC milling on overall has many advantages over other milling methods. For instance, the risks with designing and handling complicate machine parts are reduced to a large extent with minimal human intervention. Prototyping and other costs are reduced, and also the production is executed with more accuracy and speed. With constant improvements in the existing technologies, the levels of standards of production continue to be raised higher and higher.

Reference

*Image from https://www.vallma.com/