CNC milling is known to be one of the most widely recognized procedures when hoping to create complex parts. Why complex? At whatever point other manufacturing techniques like laser or plasma cutting can get similar outcomes, it is less expensive to go with them. Be that as it may, these two don’t give anything like the capacities of CNC milling.

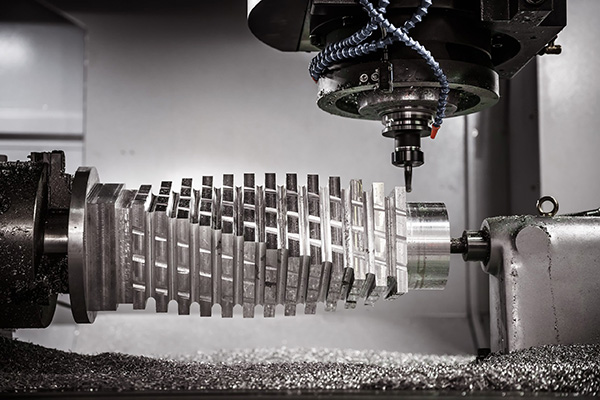

Metalworking CNC milling machines*

What is CNC Milling?

We will take a gander at the procedure, apparatus, and so forth in later passages. In any case, we should initially clarify what CNC milling implies and carry lucidity to a portion of the all the more confounding focuses on the term itself.

In the first place, individuals regularly request CNC milling when searching for processing. Machining involves both processing and turning; however these two have unmistakable contrasts. Machining alludes to a mechanical cutting innovation that utilizes physical contact to evacuate material, utilizing a wide scope of instruments.

Furthermore, all CNC milling utilizes CNC machines however not all CNC machines are for milling. PC numerical control is the thing that lies behind these three letters. Any machine utilizing CNC uses mechanized frameworks for computerizing the cutting procedure.

Along these lines, CNC machines additionally incorporate laser cutters, plasma cutters, press brakes, and so forth.

So CNC milling is a blend of these two terms, presenting to us the response to the inquiry presented in the heading. CNC milling is a substractive creation technique that utilizes PC numerical controls frameworks for robotizing the procedure.

Benefits

The benefits of CNC machines in contrast with traditional machining techniques are various; these machines utilize more significant computerization levels and decrease potential mistakes while expanding profitability and cost-viability in all cases. Here is an arrangement of the principle focal points of CNC machines:

- Consistent use: Unlike physical work, CNC hardware (excepting any glitch or support issue) can work persistently over any timeframe without a break. This extraordinarily expands profitability and proficiency.

- Consistency along with precision and repetition: With PC programming, the structure of some random item just should be modified once. The CNC machine can then consummately repeat that plan, for any request amount.

- Low Skill need: CNC machine administrators require small preparing and expertise when contrasted with manual machine administrators.

- Fewer staffs: Because PC programming controls the hardware, less experts are necessary for activity and oversight, generally cutting costs.

- Flexibility: The product can be reinvented rapidly and effectively to deliver various parts, permitting tasks to stay aware of moving client requests.

- Proficiency: This innovation utilizes PC exactness to go past the impediments of manual capacities. Progressively perplexing and multifaceted activities are conceivable with CNC machining.

- Security: Any risky wellbeing issues, for example, a jam or other machining mistake, is just inconvenient to the machine and not a security issue for the administrator, not at all like ordinary open watchman machining.

Bottom line

The benefits of CNC milling far exceed the inconveniences. Similarly, as with the coming of any new innovation, we should envision movements and changes following address new difficulties. This has never been more obvious in the assembly business, as robotization and 3D printing keep progressing. If you are searching for somebody to help with processing metals, you can essentially contact our business engineers.

Reference

*Image from https://ipmiengineering.com