Vacuum casting is a method of forcing liquid plastic into a pre-made mold, which hardens after being forced into the mold. Molds are often constructed of silicone rubber and are based on a master model, which is used to create the final product.

Who are the target customers for vacuum casting?

When it comes to quick prototyping at a cheap cost, vacuum casting is the best answer because the molds are inexpensive to produce and extremely precise; prototypes require little post-production after they are created. Each mold has a capacity of around 50 copies and may be produced in a short period. Because of the high initial tooling costs associated with injection molding, the process is more cost-effective for small batch sizes than injection molding. Vacuum casting, on the other hand, is less appropriate for long-lasting batches.

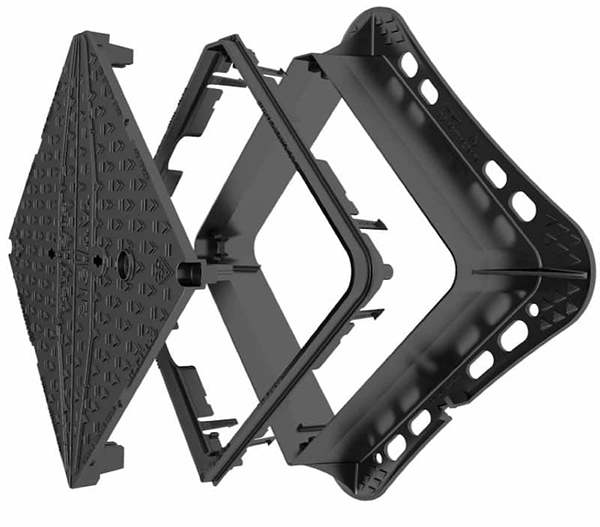

vacuum casting parts*

The Right Process

The first thing that has to be created is a master model. The client may provide this, although it is most frequently made by ProtoFab utilizing CNC machining. Metal is typically used as the primary model, but plastic is also suitable. The most critical need is that it be able to endure temperatures of 40 degrees Celsius for a lengthy period. The master model is put in a casting box, and a silicone rubber mold is created in two pieces using a silicone rubber compound. Several extremely small holes have been made throughout the mold to enable air to escape and prevent pressure from building up.

Because the mold is diametrically opposed to the master, it is sufficient to fill the mold with the material to be able to reproduce the original. However, merely pouring a liquid substance into a mold might occasionally result in suboptimal outcomes in specific cases. The construction of a vacuum chamber is thus required to push the material into even the most minor gaps to obtain a replica. After the material has filled the mold, it is placed in a hardening oven for some time until the new item is entirely solid. It is then expelled from the mold, allowing the process to begin a second time. Using the molds several times, up to a maximum of about 50 times, without affecting the quality of the duplicates is possible.

How Silicone Moulding Works Here

Silicone molding (also known as polyurethane molding name or vacuum casting) is a manufacturing process that uses silicon molds to create plastic components straightforwardly, without the significant costs and time commitments associated with steel or aluminum molds.

Silicone molds produce plastic components that are stiff or flexible and of a quality that is comparable to that of mass-produced parts.

The method for acquiring components by vacuum casting, which is created without expensive and time-consuming equipment, always starts with a standard part that has been CNC machined, which ensures the finish and quality of the finished item is maintained.

Applications

Production is at a low level. Plastic PU components produced by vacuum casting are ideal for small-scale manufacturing when volume does not justify the investment in injection molds and first-in-series parts, which may be made weeks before production tooling is completed.

Reference

*Image from https://www.industery.com/