This is the process of using elastomers to draw liquids into a mold and form objects that are needed. Vacuum technology normally used when air entrapment is not needed. Modern vacuum casting normally requires the use of computers to design the models and then send them into a system that actualizes them into real objects. The process is commonly called thermoforming because the materials are normally pre-heated and into soft pliable materials that can be created into various shapes. In models where intricate details and undercuts are needed, this vacuum casting is normally the choice.

You Need a Prototype

Through stereolithography, you need to create a prototype that can be used to make the other final products. Normally, this prototype is designed by computer applications and ensure of is of high quality so that no errors are produced at all. During this process, the owner of the products need to ensure there is maximum precision so that when bulk production has to occur, the quality of goods will be pleasing. Dimensions, looks and other enhancements are done before the main production kicks off. Always make sure you have a perfect design and have it revised before you start final production.

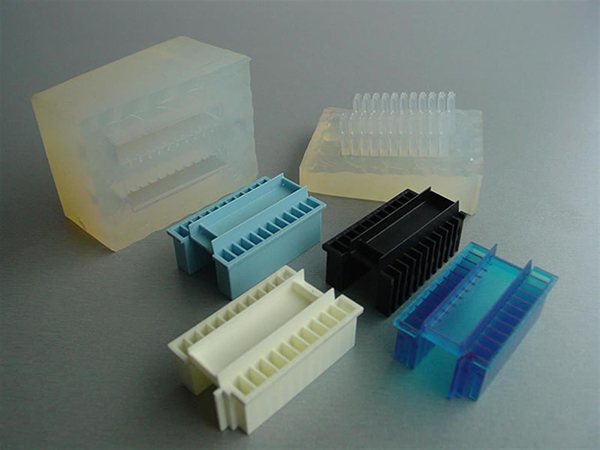

vacuum casting parts*

The Cure Stage

After the mold has been created, the two-part silicone rubber mold is then subjected under high temperatures to ensure the two parts fuses together to create the shape desired. This heating also enhances the robustness of the product making it to be durable and reliable at all times. After the reinforcement through heating has been done, the two parts are then separated leading to the formation of the final product which can now be packed for final use unless it is not as per the model required. For that reason, people have to always ensure this cure stage is not done unless the design is acceptable.

Filling the Resin

After the initial manufacture, you now have the object but it is not aesthetically complete. For that reason, always make sure you have a perfect color that would be injected to the cured object. On this process, the resin is normally injected into the object giving it the desired color. metallic powder is normally infused into the object thereby making to stand out and pleasing to the owner. after coloring, the object is returned back to the vacuum to ensure the applied color remains in place and in the perfect form.

Summary

To conclude, always make sure that you have the best kind of design and always choose your decorations prior to the process. Once the resin has been applied perfectly, it is then place on the oven to ensure it attaches well and makes the whole product reliable and wonderful. The prototype would be removed to ensure it remains for the production of other items of the same shape and colors. It is a very long process but because of the modern technology and machines, you can be sure that it will not take a lot of time at all. Vacuum casting has many application process involving car parts manufacturing, utensils and electronic covers.

Reference

*Image from https://www.ineo.es/