Vacuum casting is among the most versatile prototyping processes since it can produce an array of properties in the final products. Product designers or design engineers know that vacuum casting produces better results if used in the later development stages.

In these stage, properties and appearance must closely resemble those of the production parts manufactured using engineering polymers and high performance processes. These include elastomers, nylon, polypropylene, polycarbonate, and ABS.

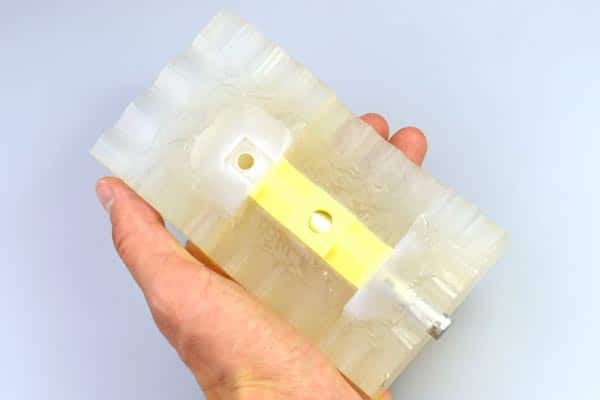

Vacuum casting is also referred to as Polyurethane or Urethane casting. It uses silicone molds to make rubber and plastic components. It’s an adaptable process that mimics injection molding to create complex parts in cast nylon and polyurethane.

Vacuum casting refers to a process of casting elastomers using vacuums to draw liquid materials into a mold. The process is mostly used if air entrapment becomes an issue, there are undercuts or intricate details, or if the materials are wire or fiber reinforced.

Basically, vacuum casting is producing rubber or plastic components under vacuum from silicone molds. The parts created using vacuum casting are precise duplicate and dimensionally accurate to the original pattern with faithfully reproduced textures and profiles.

Since the process is done under vacuum, it results in quality and smooth surface textures that are free from blemishes. Vacuum casting plays a crucial role in rapid prototyping produced parts since rapid prototyping creates rubber and plastic parts.

Vacuum Casting Applications & Characteristics

Vacuum casting is among the budget-friendly ways to create low volume, high-quality plastic and rubber parts which are similar to injection molded parts.

These parts are ideal for function, fit, and tests in the embodiment creative stages; it can be used for product design confirmation, user testing, and marketing purposes.

There are several vacuum casting gums available commercially; they can be used in creating parts that satisfy a wide array of design requirements like hardness, surface textures, temperature requirements, etc.

Vacuum casting materials help in creating completely transparent, translucent, or opaque parts.

In some instances, quality masters can be produced using the vacuum casting process to grow intricate features’ finer details of investment casting.

Is Vacuum Casting a Good Manufacturing Process?

Vacuum casting makes more economical products; this is because silicone is used in making the molds. Silicone is an affordable material in comparison to steel or aluminum and makes excellent final products. Moreover, these materials enable you to create more products from a single mold.

Vacuum Casting Materials

The following are the materials that can undergo the vacuum casting process:

- Glass filled and polyamide nylon; this material is ideal because of its high rigidity feature

- HDPR and Polypropylene; the material is ideal because of its high elasticity

- ABS; the material has strength and rigidity, making it ideal for vacuum casting

- Rubber is a highly flexible material that’s easy to use in vacuum casting

The wide array of materials used in vacuum casting reflects the designers’ individual and specific requirements for physical, thermal, and mechanical properties which their products need to display.

The materials used in this process include resins, rubbers, and thermoplastics; all of them emulate specific characteristics and properties including certain degrees of:

- Strength

- Flexibility

- Rigidity

- Translucence/transparency

- Finish/Surface texture

- Physical appearance

- Color

- UV stability

- Temperature resistance

- Hardness

Matching the materials with the desired property is complex because of the wide range of available materials.

Reference

*Image from https://www.rapidobject.com/