Die Casting Services

Metal Casts in Low Volume

For quality, customer service, and advanced production customers turn to LT Century. Our sales staff is fluent in English, Mandarin, and several additional languages facilitating easy and clear communication of your ideas and thoughts. For a free project quote within 24 hours, contact us today.

What is Die Casting?

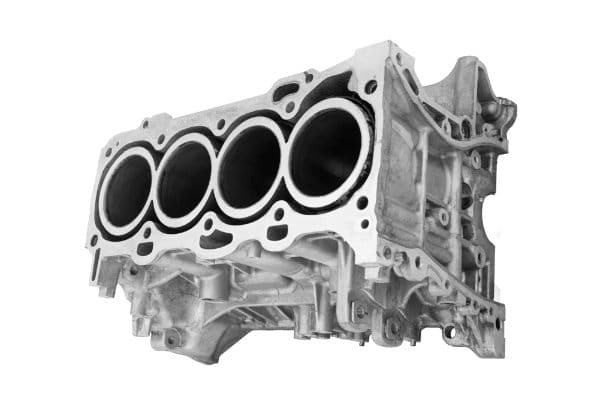

Die casting is the process of shaping non-ferrous metals into solid, seamless, and complex shapes referred to as casts. Casts made in the die casting process are used in innumerable applications across the world in almost any industry imaginable. Nearly any design can be shaped into a cast, simple or complex. Metallic casts offer many advantages including pressure, heat, and corrosion resistance desirable in automotive, aerospace, industrial, and energy fields to name only a few.

- Parts are durable and strong, resistant to pressure and weight

- Casts can be made into extremely complex designs

- A single mold can create thousands of units

- Incredible mathematical precision

- Ready for finishing treatments

No matter how complex your design the process for die casting is simple, efficient, and effective in producing thousands of units quickly and with minimal waste.

Die Cast Parts: Core Advantages

- Strength – parts are made from solid metal

- Workable – metal can be shaped into incredible complex designs

- Efficiency – a single mold can produce thousands of casts

- Brilliant – many metals offer extravagantly brilliant finishes

- Resilient – metal is resistant to heat, chemicals, and pressure

- Fast – Die casting is a fast process that produces units with extreme speed and precision.

The Die Casting Process: A Walkthrough

For thousands of identical metal parts, die casting by LT Century is the fast and efficient solution. Die casting can be used to create complex geometric designs from various metals with extreme accuracy and precision, yet the process itself is simple and straightforward.

- Using your CAD file, our own CNC shop produces your mold. Our in-house production ensures your design is never compromised, and saves on mold costs considerably. A single mold can be used to create thousands of identical units. Completed molds are sent for casting.

- Selected metals are superheated and injected into the mold. The liquid metal fills every crevice, assuring the integrity of the casted item. Once the mold is cooled, the metal will be a solid and seamless representation of your design built to incredible mathematical accuracy.

- The process is quickly repeated and the casts are taken for any selected finishing treatments before being packaged and shipped in our own shipping facility.

Die casts can be made with strong, versatile metals such as aluminum, magnesium, zinc, and more. The entire process happens very quickly, producing thousands of parts quickly so you can get on with your business. For low volume production of die casted parts LT Century is the fast and only manufacturer offering true China-direct pricing. For a free die casting quote within 24 hours, contact us today.

Start Your Die Casting Project Today

With LT Century you get:

- A free quote within 24 hours

- A free DFM within 48 hours

- In-house mold production

- Stringent quality controls

- Fast and secure delivery of completed materials

For your free estimate contact us today!