With the pandemic crisis affecting almost every industry that you can think of and the manufacturing processes. One, in particular, is 3D printing. The shutdown of many factories in China led many companies to find ways to produce the most in-demand products.

The availability of materials and digital designs for creating millions of items with the 3D printer is increasing. Some of these designs help the frontline staffs with medical hardware to use during the epidemic including ventilators, masks, and face shields. The available designs are not limited to medical products, it also applies to other industries.

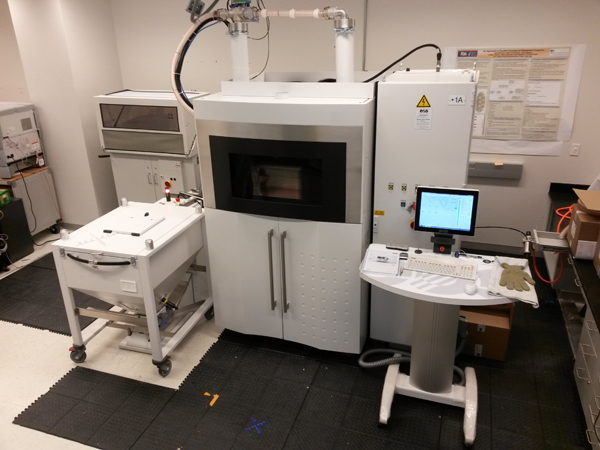

FDA powder bed fusion printers*

Applications of 3D Printing: From Rapid Prototyping to Home Projects

In the early 2000s, only large companies had access to 3D Printing. It’s because the prevailing understanding was that low-volume manufacturing means mass production in countries with low labor costs.

Yet, after two decades the patents for the first generation 3D printers have expired. Many inventors and engineers have designed and made prototypes for new printers. These makers have paved the way for inexpensive 3D printers and became accessible to many people.

The 3D printers we have today represent additive manufacturing, where the products are made layer by layer. This manufacturing process is infiltrating in different industries. Generally, the trend is changing. Instead of being used mainly for prototyping, 3D printing is being used in making products in small quantities. Reducing the need for keeping large inventories and shipping.

This trend is not small. May e-commerce sites report an increase in orders for the printing filament. This is the raw material for 3D printers. This high demand is proof that printing products at home.

3D Printing is Not Just About Plastics

Many people know 3D printers for making plastic toys and household products. While it is the most common application of 3D printing, especially for beginners, it can make other non-plastic products too. It is also used for making adaptive aids for patients with arthritis or other medical hardware. Even skateboards and other sporting goods can be made by 3D printers.

Today, 3D printers are more sophisticated and the number of items it can make is rapidly expanding. There are ceramic and metal 3D printers available that can produce expensive medical implants and rocket engines. 3D printers can also produce inexpensive brackets to support bulk products, thus, lowering its cost.

Soon there will be pharmaceutical products, electronics, and bulk items like furniture that will be added to the long list of products made from 3D printing.

Conclusion

There could be hurdles for 3D printing like the availability of filaments or the disruption of the supply chains. The new metal printers remain expensive but the people behind the technology are not stopping until they can surpass these hurdles.

One of the recent developments in the recycling technology that allows for the creation of raw material from plastic waste. There is a long way to go for 3D printing technology. But the demand for unavailable and costly products might speed up its developments.

*Image from https://www.fda.gov/