Sheet metal is one of the widely used materials and processes around the world today. Its most popular application is in the construction industry, but it does not limit its capability here, as sheet metal is versatile material that can provide a variety of benefits. Sheet metal fabrication is the process when the material has undergone bending, welding, and molding. This is a long process, but the results are remarkable and definitely worth the wait.

The development of different technologies in sheet metal manufacturing like the most recent lights-out manufacturing has made its fabrication more advanced and efficient than before. The used of sheet metal in many applications particularly by the construction industry and other by-products are made possible by its many characteristics.

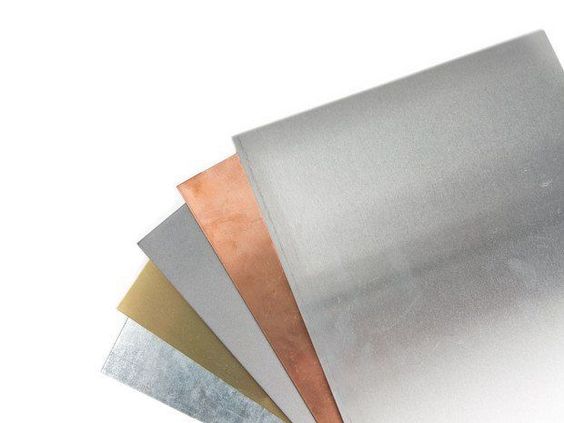

sheet metal materials*

Applications of Sheet Metal

The most well known use of sheet metal is as a construction material but being a versatile material, its applications are everywhere. It is used in every industry imaginable including in mining, catering, farming, hospitality, manufacturing, shipping, medical, transport, and aviation.

Other than its industrial applications, it is also widely used in domestic applications. You can find the sheet in metal in kitchen countertops, in many home appliances and even as a part of interior design like the new punched metal screen in modern homes.

Benefits of Using Sheet Metal

Sheet metal as a product, which includes steel, mild steel, aluminum, and stainless steel provides a set of advantages. This makes them a favorite material for engineers, contractors, designers and even for the ordinary people. Here are some of its benefits.

– Malleability

Sheet metal manufacturing has become popular because this material is characteristically thin and has low density. This makes it more malleable and easy to form into a wide array of products and objects. Malleability is one of the top characteristics that manufacturers and engineers are looking for on their material.

– Durability

Another endearing characteristic of sheet metal is its strength. This component of sheet metal is durable and resistant to corrosion, which makes it an ideal material in construction for roofing and siding. It is also easy to change a portion of sheet metal when there are damages as compared to other construction materials used for the same purpose.

– Weather Resistant

During sheet metal manufacturing, there are chemicals added to make them resistant to corrosion, moisture and ultra-violet rays. This makes them also resistant to water. When of part of the sheet metal is scratched, these added chemicals also prevent them from sustaining further damage.

– Versatility

This characteristic was mentioned earlier in the article, and it is worth mentioning again. During planning and design, the engineers and architects imagination is limitless when it comes to their building projects. Sheet metals are widely used not only as a roofing material but also, in a host of other applications. Owing to its versatility, you can also find sheet metal in automotive, aerospace, healthcare, food service and many other industries. Sheet metal is even used to create an artwork.

– Easy to Transport

Sheet metal is lightweight, and because of this characteristic, it is easy to transport. This material is also manufactured into thin sheets that allow stacking, making its storage less complicated.

Advantages of Using Sheet Metal

The great thing about sheet metal is this material is entirely malleable, which means that they can be turned into another shape or product quite easily. This process is sheet metal fabrication and usually involves bending and shaping the metal into the required thickness and shape. An expert fabricator can turn the sheet into complex and hollow forms depending on the design like those found in the bodies of the car, airplane wings, soda cans, and even hospital tables.

The technological advancement in recent years has turned sheet metal manufacturing into a more advanced material. In turn, sheet metal fabricators can now have even more sophisticated products out of this material for every purpose. They are now using tools that are more efficient in cutting, slitting, seaming and perforating the sheets. One example is the use of CNC machining or the use of computers to control the machine and the tools. This allows greater precision and ability to produce shapes that are even more complex accurately and quickly without adding to the costs. This technology combined with different methods and techniques helps create the desired outcome to complete engineering and structural projects.

One company that provides prototypes and parts that are made of sheet metal is LT Century. They can be your one-stop provider of sheet metal for every step of your manufacturing process. This company provides different sheet metals and alloys in prototypes, low production, and small batch orders. They offer China-direct pricing for high-quality components and metal parts. Their sheet metal manufacturing professionals in LT Century are ready to create intricate metal products for a variety of applications wherever you are located.

Reference

*Image from on https://makezine.com