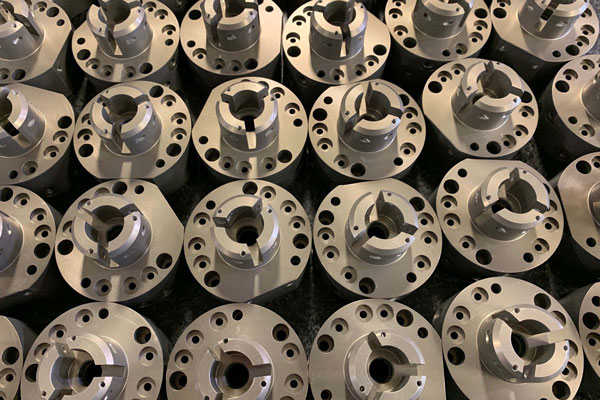

The world of manufacturing is undergoing a profound transformation, driven by the rapid advancement of artificial intelligence (AI) and automation technologies. At the forefront of this revolution is CNC machining, a cornerstone of modern manufacturing, which is being reshaped by the integration of AI and machine learning algorithms.

The Rise of Intelligent CNC Machining

CNC machining, renowned for its precision and efficiency, is evolving into a new era of intelligence. AI and machine learning are being leveraged to optimize various aspects of the CNC machining process, from predictive maintenance to adaptive toolpaths and even autonomous machining.

Predictive Maintenance

One of the key challenges in CNC machining is unplanned downtime, often caused by machine failures. AI-powered predictive maintenance systems are addressing this issue by analyzing real-time data from sensors embedded in CNC machines. These systems can identify patterns and anomalies that indicate potential problems, allowing for proactive maintenance and minimizing costly downtime.

Adaptive Toolpaths

Traditional CNC machining relies on pre-programmed toolpaths, which can be inefficient in complex scenarios. Adaptive toolpath algorithms, powered by AI, are changing this paradigm by dynamically adjusting toolpaths based on real-time feedback from the machining process. This results in optimized cutting strategies, improved surface finishes, and reduced machining time.

Autonomous Machining

The ultimate goal of AI integration in CNC machining is autonomous machining, where machines can operate with minimal human intervention. While this is still an emerging field, significant progress is being made. AI-powered systems can analyze CAD models, generate optimal toolpaths, and even make real-time adjustments during machining, paving the way for a future where CNC machines can operate independently.

Real-World Applications

The impact of AI and automation in CNC machining is already being felt across various industries.

- In the aerospace industry, AI-powered CNC machining is enabling the production of complex components with unprecedented precision and efficiency.

- In the automotive sector, AI is streamlining the manufacturing of intricate engine parts and body panels.

- The medical device industry benefits from AI-driven CNC machining in the creation of custom implants and prosthetics.

Challenges and Opportunities

While the integration of AI and automation in CNC machining offers tremendous opportunities, it also presents certain challenges.

- The need for skilled professionals who can operate and maintain these advanced systems is paramount.

- Ensuring data security and protecting against cyber threats are critical considerations.

Nevertheless, the potential benefits far outweigh the challenges. As AI and automation technologies continue to mature, CNC machining is poised for a new era of innovation and productivity.

Conclusion

CNC machining is undergoing a remarkable transformation, fueled by the integration of AI and automation. From predictive maintenance to adaptive toolpaths and autonomous machining, these technologies are revolutionizing the industry, enabling manufacturers to achieve new levels of efficiency, precision, and productivity.

As we move forward, the synergy between CNC machining and AI promises to reshape the landscape of manufacturing, driving innovation and growth for years to come. Visit the LT Century website to learn more about their services and capabilities.

Reference

*Image from https://robersontool.com/