There is no doubt that the popularity of 3D printing is increasing almost every day. Over a decade ago, people didn’t have access to several three-dimensional printers to use. The truth is that 3D printers are now almost everywhere you go today. When following the same trend, it looks as if CNC milling and routing is a bit behind. Today, the same CNC milling and routing are now closing the gap for real. The general phrase “CNC machines” consist of a lot of other subsections of items for the group. CNC routers, CNC mills, waterjets, laser cutters, 3D printers are also under CNC machines.

When talking about CNC machines, it has to do with items using a full automation process. These machines have the capability to drill or cut materials with the help of a router or spindle. In a nutshell, the best phrase to describe CNC machines is “subtractive”. With 3D printing, the process is additive because they add to the system. One thing is sure, 3D printing and CNC machining are production processes to stay. To get a picture of these processes, you can continue reading.

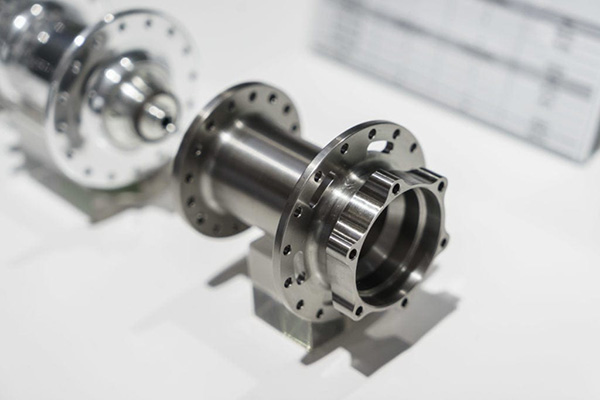

Precision CNC machining products*

The Geometry Versatility Of 3D Printing And CNC Machining:

When talking about geometry versatility, it means the parts and shapes an item can produce. With this factor, three-dimensional printing serves better than CNC. CNC machines may find it difficult to fabricate parts with overhangs, but three-dimensional printers can do them. The CNC application will need several features for a setup to do the same job that 3D printers resolve almost immediately. When the part is not clamped or registered, the process becomes difficult for CNC machines. 3D printing makes the creation and designing of parts faster and reliable than the CNC machining process.

The Cycle Time Of CNC Machining And 3D Printing:

In most cases, professionals in the industry refer to a cycle time as the duration in creating a part. Most clients using 3D printing often say the duration of creating a part is fast and efficient. With 3D printing, you’ll find a plethora of other methods that help to finish parts. SLA, DLP, FDM, and more are some reliable technologies operating with 3D printing. Besides, sometimes, these 3D methods can also experience a slower time for creating parts. Remember that CNC is all about subtracting from the material to help in a faster process. It implies that CNC machining can as well produce a part in a reliable and faster period. With cycle timing for both processes, it is easy to say that CNC is faster and better than 3D printing.

Metal 3d printing for aerospace**

Setup Duration For 3D Printing And Computer Numerical Control:

The truth is that 3D printing may not need more setup time like CNC. It means that CNC involves creating a setup with several minutes more than its counterpart 3D. When talking about three-dimensional printing, you may only need to drop the design into the slicer that works. With a bit of tweaking, the 3D printing process can begin work almost immediately. People that deal with CNC routing and milling will have to spend more time designating. For instance, the operator will have to select the best cutter that can produce a better design. The depth of cutting the material and how fast the process can work are other factors with CNC. Will the cutter in operation strike the clamps? People that engage with CNC will have to ask these questions before continuing. In a nutshell, the setup time for 3D printing is faster than most CNC machining processes.

Material Choices For CNC Machining And 3D Printing:

With this feature, CNC machining comes on top. Most three-dimensional printers cannot work on several materials. It means that a limitation can take place when talking about material choices for 3D printing. For instance, nylon, PLA, ABS, and more are material limitations that you can get when using 3D printing. Wood filaments can also work for 3D printing, but may not be a reliable material to use. People that make use of a CNC machine may not even notice any limitation as in 3D printing. CNC machines can cut metals, composites, plastic. wood, and much more. Even if you want to deal with aluminum, brass, or other softer metals, CNC machines will work. With titanium and stainless steel metals, CNC machines will give the best result. CNC processes will help to create success with practical parts and artistic works. When considering material choices, the only way to say it is that CNC remains the best option. While the process you choose depends on the nature of the job, but these factors can help make the best decision.

*Image from https://hwacheonasia.com/

**Image from https://www.btec3d.com/