Among the fastest growing and the most lucrative sectors in China, rapid prototyping is unarguably one of the leading ones. China is the global hub for many manufacturing sectors. Starting from kids’ toys to electrical machinery, the country boasts of supplying oodles of manufactured goods to developing as well as so called established economies at very reasonable deals. Of late, its domination in various fields has raised so much so that BRAND CHINA has become the synonym for manufacturing sector.

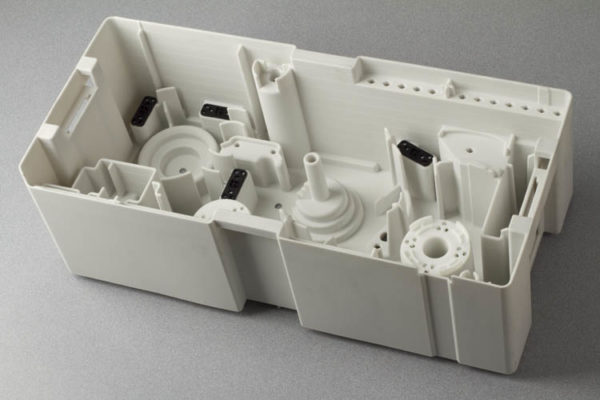

rapid prototyping part *

Prototyping industry in China:

Prototyping industry in China was a big revolution couple of decades ago. Like in many other sectors, the country wanted to have a big share in the prototype market, which, for some reasons , had mixed opinions among various nations, particularly the west. While it is a fact that manufacturing costs in china are cheaper than the first world countries like the USA or UK, often there raises a question of quality with chinese products.

Is it ok to outsource Prototyping to China?

Although it is common to outsource mass production to China, outsourcing development of Prototypes is still a rare sight. The reason for this is one because as mentioned earlier- the quality of the products and two- the DETTO product that you get after prototyping. It means that if your design has some defects for any reason, it will not be changed in the finished product. They give you the EXACT prototype that you have designed in the preliminary version.

whereas in the west, the case is different. Any defects in the model are rectified in the preliminary version so that the final outcome is free of errors. It is hard to take TRIAL AND ERRORS when you are planning production at a very large scale. This not only wastes the valuable time of the organizations but also results in huge loss of money. So it is important to make sure that your model is error free before deciding to outsourcing to a chinese company.

Also communication is a key in getting the desired output especially when you are dealing with an external party. Good interaction ensures that both the client and service provider have better understanding of the product and design. Any changes that have to be made in the model should be intimated beforehand to avoid loss of money and resources. So make sure that you maintain a proper communication and good rapport with the company that you are outsourcing to.

Points to remember about China Prototyping:

There are many myths surrounding manufacture of goods and services in China. Prototyping in china is also misunderstood in many senses. The fact that they only deliver the exact product specification creates confusion about their production capacity. But with proper channelization and specific guidelines, chinese companies can debunk all the myths and mould stunning Prototypes.

Chinese companies are cost effective:

It is true that chinese companies are flexible with costs. But you should also understand that depending on the complication of the model, it can sometimes be an expensive affair. The biggest advantage with chinese companies is they can come down to your budget. This can be of great benefit particularly with Prototypes as you already spend so much of money on research and development. If you want to get your work done in moderate budget you can outsource it to China but be sure to give the model specifications accurately.

They are more responsive:

chinese companies are more responsive to clients’ demands. They are more willing to work in a competitive environment and are pro-active in adhering to business requirements. China is a very huge market willing to offer services in varied types of budgets. This is particularly advantageous for medium and small scale companies who are budget constraint.

They are on time and competitive:

chinese companies are known to be very punctual at work and deliver goods and services on time. They are hardworking and attentive and go that extra mile in meeting the deadlines. Getting products on time means a lot for you and this directly impacts your profitability.

They can create replicas with ease:

There is a tendency of blaming chinese companies for their quality and lack of uniqueness. But they actually do it only on demand of clients and they are definitely not duplicates. You can suggest an idea while the product is taking shape and they are implemented without a trace of copying existing designs. Your idea is ONLY taken into account and given a totally different shape.

Contrary to existing notions of the west, there are many companies which have high-tech equipment in prototype manufacturing in China including CNC machines and additive manufacturing. Statistics show that China has spent $1.1 billion on additive manufacturing which makes it one of the fastest growing Prototype development nations in Asia. Companies are taking advantage of this situation as Prototype manufacturers are offering their services on a relatively lower cost to stand competitive with their rivals.

Reference

*The picture is from http://www.polyflexpro.com