Milling is a process of shaping a workpiece, either made of wood or metal. It can be used to flatten the surfaces, bore, drill, cut, etc. They are essentially used to provide shape to a piece that further helps where ever it is needed. Milling is a very important process in various industries and is used for equipment making, furniture making, etc. With the evolving era, the mechanical milling machines are being replaced by the computerized one called CNC milling machines. These machines require less manpower and are automated machines. They not just help people but provide better and more accurate milling.

About CNC Milling

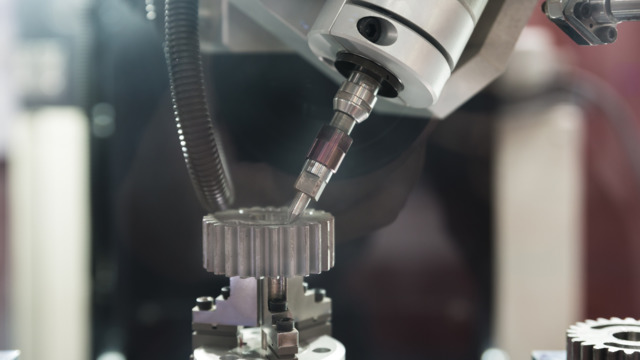

Computer Numerical Control milling machines are those that are computer-aided. They work on computer programmed codes that let them know how to shape and build an object. The codes made by the programmer help transform a virtual image into a real object by shaping them using various milling tools. The machine usually understands the 3D view of an object. The codes are made in such a way that they are converted into numbers of the Cartesian plane for the CNC milling machine and help them have a 3D view. After understanding the views from all different angles, the machine works as a robot to work on the workpiece as per the dimensions and views of the virtual image.

5 axis cnc machining*

Benefits of CNC Milling

Several benefits come from a computerized milling machine. They include the following:

- Better milling: Humans may be highly skilled in performing a task, but the finishing and milling of a workpiece by a machine as per the dimensions are far better than the human work.

- Accuracy: Accurate value is the nearest value to the true one. CNC milling working based on computerized numerical codes, is very accurate and provides the same or very near value to the virtual one. CNC machines make no error until there is a glitch with code which is a human error.

- Speed: Humans take time to bring a workpiece to perfection while milling. The milling machines are rapid and have speed greater than humans along with a high degree of accuracy while working on a task.

- Durability: These milling machines are highly durable and can work throughout the day and also during weekends. They do not stop until they come across some breakdown which needs repair.

A CNC machine can be of high importance especially in an industry that requires high production. Easy to use and code the dimensions any person can be taught to use it that gives compensation to the manpower lost by its replacements. These machines are available in the brick and mortar stores and also in online shops. These should be bought after having proper knowledge and choosing from several machines available. With high durability, these machines should be given proper checks from time to time to increase its life span. Being a onetime investment, they can be the best fit for those in need.

Reference

*Image from https://www.ien.com/