LTC Prototype Blog

Stay in touch with our blog to get the latest happening around us

5 Reasons to Use CNC Machining for Rapid Prototyping

In the fast-paced world of product development, rapid prototyping plays a crucial role in bringing ideas to life quickly and efficiently. Among the existing rapid prototyping technologies, CNC machining stands out as a reliable and versatile option. This process...

Exploring Flexibility and Affordability of Vacuum Casting in Production

Vacuum casting stands out as a versatile and cost-effective manufacturing process that has found wide utility across numerous sectors, including automotive, aerospace and medical device manufacturing. This article delves into the intricacies of vacuum casting,...

How to Minimize the Environmental Impact of Plastic Waste

Plastic disposal is a major challenge for both urban and rural areas. Plastics are widely used for packaging, but they often end up in landfills or litter the environment. Rapid prototyping companies produce plastics that are biodegradable, but they still take time to...

How to Save Money on Production with Vacuum Casting

Vacuum casting is a popular technique for prototype development and can be used at any stage of production to make multiple changes to the design of a product. With this method, complex designs can be turned into new prototypes in less than a month. The process is...

What Are the Ways We Use Vacuum Casting in CNC Machining?

Vacuum casting and CNC (Computer Numerical Control) machining are vastly different manufacturing techniques. The former is a rapid prototyping and production process used predominantly with polymers, while the latter involves the precise removal of material using...

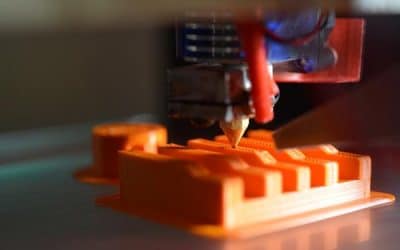

What Is the Process of Rapid Prototyping Services?

The desired result is one of many variables affecting the rapid prototyping process. Based on your objectives and financial constraints, RP experts can assist you in selecting the best strategy. What to anticipate during the procedure and tips for getting the most out...

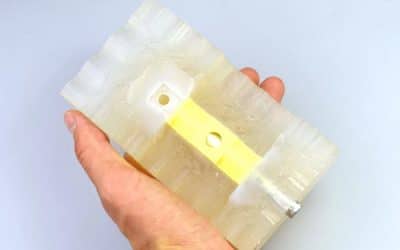

Vacuum Casting: Everything You Need to Know

Vacuum casting is among the most versatile prototyping processes since it can produce an array of properties in the final products. Product designers or design engineers know that vacuum casting produces better results if used in the later development stages. In these...

Rapid Prototyping Services: A Complete Guide to Online Resources

Rapid prototyping is a very important thing that has to do a lot with the business strategies and the other stuff. There are a lot of things that are to be learned when a person is learning about marketing and product raising. When it comes to marketing and...

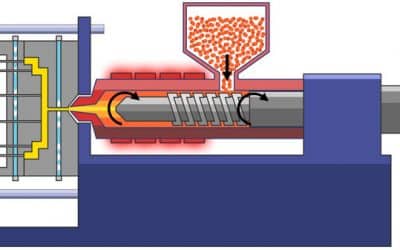

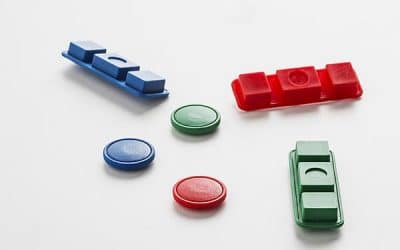

Learn About the Plastic Injection Molding Machines and Types of Equipment In Detail

There are a lot of plastic injection molding services that are available in a lot of factories that manufacture plastic injections. These factories are the ones that are available for the people to get their hands on the molds that are made for the injections for...

How Does Plastic Injection Molding Works?

Before you dive into the topic of plastic injection and how it works, here is something which you have to know. The definition of the said matter. The injection molding which happens to have for the fast process and is used for the production of the large and the...

Vacuum casting Saves Time and Money in Product Development

Consider Vacuum casting for fast, flexible, and cost-effective plastic parts. Vacuum casting uses a vacuum chamber to make parts from a silicone mould. It has advantages over injection moulding, 3D printing, and CNC machining. Vacuum casting saves time in product...

Revolutionizing Manufacturing with Vacuum casting: Exploring its Applications and Benefits

Vacuum casting is a game-changing technology in manufacturing, also known as urethane or polyurethane casting. This process is more versatile than injection moulding and CNC machining, with several advantages. It is used in many industries such as automotive,...