LTC Prototype Blog

Stay in touch with our blog to get the latest happening around us

Vacuum Casting: Everything You Need to Know

Vacuum casting is among the most versatile prototyping processes since it can produce an array of properties in the final products. Product designers or design engineers know that vacuum casting produces better results if used in the later development stages. In these...

Rapid Prototyping Services: A Complete Guide to Online Resources

Rapid prototyping is a very important thing that has to do a lot with the business strategies and the other stuff. There are a lot of things that are to be learned when a person is learning about marketing and product raising. When it comes to marketing and...

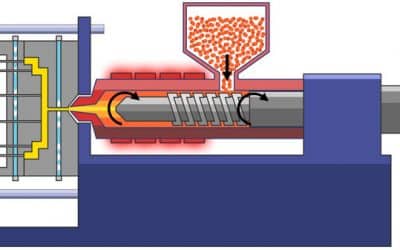

Learn About the Plastic Injection Molding Machines and Types of Equipment In Detail

There are a lot of plastic injection molding services that are available in a lot of factories that manufacture plastic injections. These factories are the ones that are available for the people to get their hands on the molds that are made for the injections for...

How Does Plastic Injection Molding Works?

Before you dive into the topic of plastic injection and how it works, here is something which you have to know. The definition of the said matter. The injection molding which happens to have for the fast process and is used for the production of the large and the...

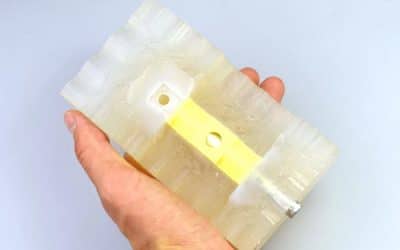

Vacuum casting Saves Time and Money in Product Development

Consider Vacuum casting for fast, flexible, and cost-effective plastic parts. Vacuum casting uses a vacuum chamber to make parts from a silicone mould. It has advantages over injection moulding, 3D printing, and CNC machining. Vacuum casting saves time in product...

Revolutionizing Manufacturing with Vacuum casting: Exploring its Applications and Benefits

Vacuum casting is a game-changing technology in manufacturing, also known as urethane or polyurethane casting. This process is more versatile than injection moulding and CNC machining, with several advantages. It is used in many industries such as automotive,...

What are the Products Available from Rapid Prototyping Services?

Rapid prototyping services have revolutionized the product development industry, enabling designers and engineers fast turn their ideas into tangible prototypes. Rapid prototyping involves the creation of a three-dimensional model of a product, typically using...

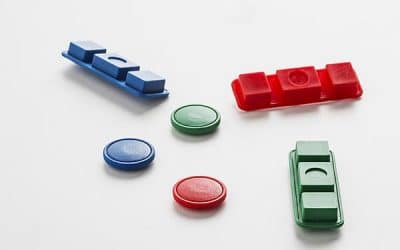

Unlocking the Power of Plastic Molding: Key Benefits for Manufacturers

Plastic molding makes plastic parts and products. Molten plastic is poured into a mold and cooled to make the desired shape. Plastic molding is popular for manufacturers because of its benefits. We'll discuss why plastic molding is useful for manufacturers....

Discover the Advantages of Plastic Injection Molding in Manufacturing

Plastic injection molding has revolutionized the manufacturing industry, offered numerous advantages and unlocked endless possibilities for manufacturers. In this blog post, we will explore the key benefits of plastic injection molding and delve into why it is a...

Vacuum Casting: A Versatile and Cost-Effective Manufacturing Process

It is a versatile and cost-effective, making it useful in many sectors. Automotive, aerospace, and medical device manufacturers utilise it to build moulds for casting complex geometries using a vacuum. This article discusses vacuum casting, its benefits, and its uses...

Vacuum Casting: An Overview of the Process and Its Applications

Traditional production methods make high-quality parts expensive and time-consuming. However, technology has enabled the creation of new production processes like vacuum casting, which offer exceptional surface detail, dimensional accuracy, cost-effectiveness, and...

How Do Rapid Prototyping Services Help the Manufacturing Business?

Rapid prototyping is a powerful tool for manufacturing businesses that allows for the physical prototype’s creation quickly and easily. By using 3D printing, CNC machining, and other technologies, rapid prototyping services can help businesses to test and refine their...