Prototyping is a crucial part of product development because it will keep the business competitive. Product development remains complicated despite many advancements in the process. For this reason, many companies are looking for different methods for this step to be more efficient.

A prototype is the physical representation of a concept, and it is often used to test the design and evaluate its functionality. With this aspect, prototypes should be quick, safe, and less expensive to make. That is where rapid prototyping comes in.

As the name suggests, rapid prototyping comprises different manufacturing methods used to quickly and economically produce a part or product, typically through additive techniques. Through rapid prototyping, product designers and engineers can create proof-of-concept models using CAD data. It makes the process faster than ever and can easily execute revisions on the designs based on feedback and testing.

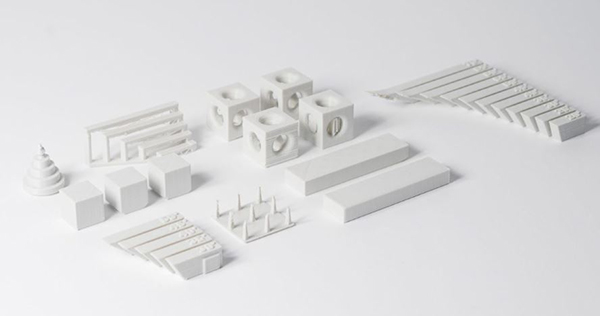

3D printing molds*

Why is Rapid Prototyping Important?

There are many reasons why a prototype is important in product development. Other than having a physical representation to see, touch and try, stakeholders also need proof of the design before approval.

Another reason why a prototype is vital is to test the viability of a certain idea and to see if the design fulfills all the requirements. This prototype is also needed to evaluate the product and look for improvements before going into full production. Prototypes also serve as a bridge between design and final production run. You can test the market with it and analyze their feedback on the product.

Prototypes are divided into two: form and function. Form is done to see what the concept and design will look like. This prototype will have the exact look of a completed part, but it will not function. The other kind can function properly and will not look finished. When these two elements are combined, you will have a 3D model that looks right and functions correctly.

Role of Rapid Prototyping in Product Development

Rapid prototyping is an important component of the design process. Its advantages are new to product designers and engineers. With a full-scale model from a design, we can see the flows or identify the areas with challenges, before it goes to full production.

The traditional prototyping techniques use clay or wood to create mock-up displays. Some resort to fabrication, which takes longer, is expensive and challenging to make.

The mock-ups are visualizations of the shape and dimensions of the concept, while the fabricated models can represent the whole design with its functional parts. The latter can give the designers a chance to test the function and check if it works.

Rapid prototyping includes a wide range of technologies that can create parts and products directly from the CAD data. These techniques are fast and accurate, with room for customizing any shape. Some of these methods are CNC, 3D printing, SLS, SLA, and others. The final part will look like the finished product, which is the most critical in product development.

Reference

*Image from https://www.econotimes.com/