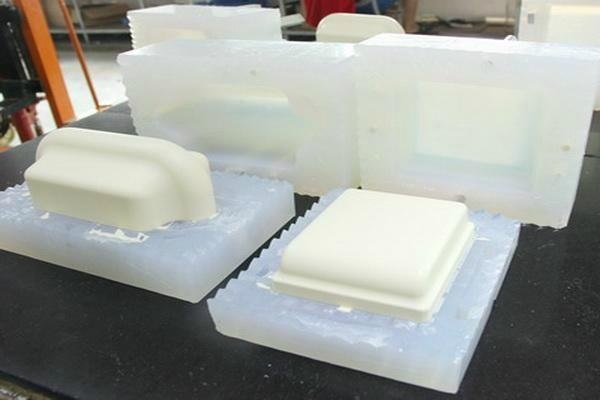

Vacuum casting is also known as the vacuum duplication method. One of the reasons why the name vacuum duplication is given is because the duplicate copy or model or the original products can be easily made through the process of vacuum casting. Vacuum casting is not some very quick process like rapid tooling or CNC machining services. Vacuum casting takes time, as there is a process in which after the master model (i.e. the original product) is kept in the silicon rubber case, it is then heated up to certain degrees, then cooled off and then the original model is removed and then again the casing is closed and heated after sealing. Then, it silicon rubber casing after cooling is again placed under the vacuum casting machines and then the liquid (resin or wax) (plain or colorful) is poured into the silicon rubber casing through a pipe (without opening the seal of the silicon rubber casing) after which it is again heated up to 70 degrees Cl. Then, cooled off, and the silicon casing is opened and you get the duplicate of the original product.

Vacuum Casting

So, suppose there is an intricately designed plastic item like a plastic block, or plastic piston, or nuclear valve, and any industry is in the process of creating the duplicate or copy of the model, and then it’s a very time taking process. It cannot be done easily with the injection tooling method, that’s for another case. So, you can imagine for instance, if 100s of plastic piston/blocks which has an intricate design is to be made, then the industry will require in its manufacturing sector that has many heating ovens and silicon rubber casings, and the resins or liquids and the coloring agents, etc. Therefore, vacuum casting is a time taking process. It is not only the heating that takes time but also the cooling process. And if there is any mistake in or hasty work done during this entire process, then it can happen that the design of the original model can be imprinted in a wrong shape or manner.

plastic vacuum casting*

How Defect Comes in Vacuum Casting

In such a case, you will get a defective product. So, many times when you get the nuclear valves and other parts like piston, etc. which doesn’t fit or work out for the purpose for which it was made, then you can understand that during the vacuum casting process some haste was done or the cooling or sealing or removing the original product from uncooled (hot/lukewarm) rubber casing led to such a shape or design. Let me give you another instance, for example, a tiffin box with a cover or lid that doesn’t close properly is loose. You wouldn’t have checked at the time of buying but after using it for some days you can see it doesn’t fit, why? The reason is the defect due to improper handling during manufacture. This is one of the reasons why the companies that sell such products are mostly looking for a good vacuum casting industry so that with their efficacious working their products come out as a good quality product.

Reference

*Image from https://www.diytrade.com/