The spread of three-dimensional technologies has simplified manufacturing, lowered costs, and increased production flexibility. 3D scanning and virtual modeling allow for precise shape measurement and digital model replication, while 3D printing allows for quick and low-cost manufacturing. In some circumstances, 3D printing is even cheaper than vacuum casting. This saves money when making small or medium-sized batches of plastic items from a sample.

Vacuum casting is a considerably faster and cheaper method than doing a factory issuance. Silicone molds are less expensive than conventional tools, and they can hold up to 50 fillings depending on the issue.

What exactly is vacuum casting?

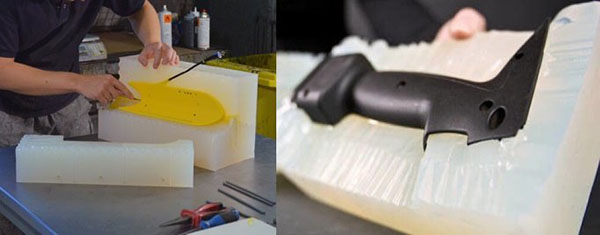

Vacuum casting is the process of pouring elastomers in a vacuum in a silicone mold. A vacuum is used to help draw the liquid material into the mold while pouring elastomers. The majority of companies have chosen to adopt vacuum casting for speedy prototypes and the absence of air bubbles.

Vacuum casting can be used to make very complicated components such as wire reinforcements, fibers, and so on.

Thermoforming is another term for vacuum casting. This is mostly due to the fact that it is one of the techniques that necessitates rapid prototyping when the plastic sheets are preheated.

vacuum casting services*

When should you consider vacuum casting to achieve your goal?

- If you need a small or medium batch, as written above. Of course, you can create only one copy.

- Need prototypes? You may want to assess the product’s design, assemblability, and functionality before making traditional tools. Or you need a research sample.

- Metal molds are more expensive to create than silicone ones.

- When doing a customer survey with a pilot product evaluation.

- When deadlines are tight and the batch must be ready quickly.

Vacuum casting ensures a precise duplicate of the master model, i.e. H. The products are identical to those created using a normal injection molding machine.

Vacuum casting of polymers requires the following steps:

- Making the master model. A pre-existing product or a 3D printed prototype can be used as a template. You can send drawings or sketches and masters will model them in 3D.

- Pouring a silicone mold. The silicone is put into the master model form and polymerized with a vacuum mixer.

- Testing and refining, the product’s quality is checked and the model is modified if necessary.

- Product creation by pouring material into a mold. The color range of plastics and polyurethanes allows you to pick the perfect ones. The texture can be smooth or rough, glossy or matte. Various materials can be combined to obtain desired physical and mechanical features like impact resistance, heat resistance, flexibility, etc.

Vacuum casting is used to make plastic cases, souvenirs, toys, parts, packaging, and more.

Materials that are used in vacuum casting

Two-component liquid polyurethanes are commonly utilized in the vacuum casting technique. Different physical and mechanical qualities can be achieved in the ultimate product by adding different components to the liquid polyurethane. These can be the features of fundamental technical plastics such as polyamide, polyethylene. The beneficial properties of polyurethanes, which can simulate the appearance and quality of rubber with a hardness ranging from 45 to 97 units, as well as heat-resistant materials capable of withstanding temperatures of up to 120 ° C.

Reference

*Image from https://www.jtproto.com/