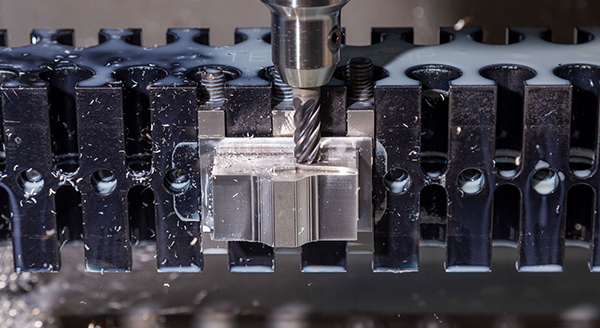

In the current manufacturing set-up, CNC machining is one of the most popular production techniques with manufacturers and clients alike especially when it comes to making parts and prototypes.

CNC machining has taken over completely the conventional production process and comes prototyping machining which is nothing but using computers to make a working and functional prototype.

In this post, we are going to briefly discuss some of the reasons why CNC machining is the perfect technique used when it comes to prototype production.

Complete automation

During the 1980s and ’90s, engineers and designers used to operate center lathes, vertical millers, shaping machines, and operating routes when it comes to the creation of prototypes. There are plenty of benefits that come with using CNC machines to created prototypes and one of them is the process it completely autonomous.

For this reason, most manufacturers are opting to use this technique for creating their functional prototypes, this is the perfect manufacturing technique including fabrication. Prototype machining is the best choice as it provides you with expedient, efficient, and precise production

Before delving into full production, some qualities need to be met so that you have a working and real prototype that will be very similar to the end-product.

Cost-effective and economical

Prototype machining is economical and affordable allowing you to minimize input while maximizing its output. For example, in the past; conventional machining required the recruiting of manual skilled labor which was costly.

On the other hand, using CNC prototyping machines requires just a single operator to control and monitor the whole prototyping process allowing you to take advantage of the huge economies of scale.

Some of the industrial sectors that take huge advantage of the prototyping CNC machining are agriculture, dental, construction, automotive, firearms, electronic, military, construction, metal works, and hospitality.

CNC machines employed in prototyping

CNC machines employed in prototyping

CNC machining is commonly known as computer numerical control, in simple terms it’s a production process used to create prototypes using machined parts. For modern machines, they use computer numerical control rather than old conventional and machining tools which used mills, grinders, lathes, or routers.

The new machines utilize special software known as G-code. G-code is a machining language that ensures there is precise control of features such as location, coordination, speed, and feed rate. This specialized software can control and monitor different aspects of the machine.

Having a single operator who monitors everything is much more superior to having multiple workers doing more or less the same thing. You’ll not incur huge labor expenses allowing you to significantly cut down on the overall manufacturing process.

CNC prototyping allows both the client and producer, to see the design and specifications of the prototype, gauge its viability and functionality before mass-production is rolled out.

There are plenty of advantages that come with CNC prototyping machining, regardless of the type of business you are engaged in you’ll still enjoy the same benefits, the opportunities and advantages that come with thesetechniques are endless.

Reference

*Image from https://www.cheyennemfginc.com/