The technological world is advancing by leaps and bounds, and not being at the latest implies a disadvantage with respect to the competition. Sectors such as automotive, aeronautical or rail, among others, constantly increase their technological capabilities, and for this, they need the best production systems, capable of offering the finest precision in record time. And one of those new technologies is the 5 CNC axis machining system, you already see a lot of factories around the world, such as in China, making use of these kinds of machining systems. We explain the operation and advantages of the 5-axis CNC machining system. These machine systems are the cutting edge in product creation. And you need to understand how it can better your own production process for rapid prototyping.

Operation and Benefits of 5 Axis CNC Machine

To understand the operation and benefits of 5-axis machining, we must first know the predecessor system that serves as the basis for the following models, multi-axis machining. This mechanical production process is characterized by the use of computerized numerical control tools. These systems are capable of producing rotations on one or more axis, allowing to alternate from 3 axis in its beginnings, up to a total of 5 currently, with the 5 axis CNC machining system. These advances are linked to software improvements (CAM programming software) that allow a greater configuration of parameters in search of greater productive efficiency.

Functioning as complex as it may seem is not difficult to understand. When we speak of 5 axis, we refer to the number of trajectories that the cutting instrument can travel simultaneously. That is, in a single procedure you can work the five planes of the piece. Specifically, these displacements are made by crossing the 3 linear axis (X, Y, Z) and rotating around the axis A and B, being able to reach any point of the piece regardless of the position in which it is.

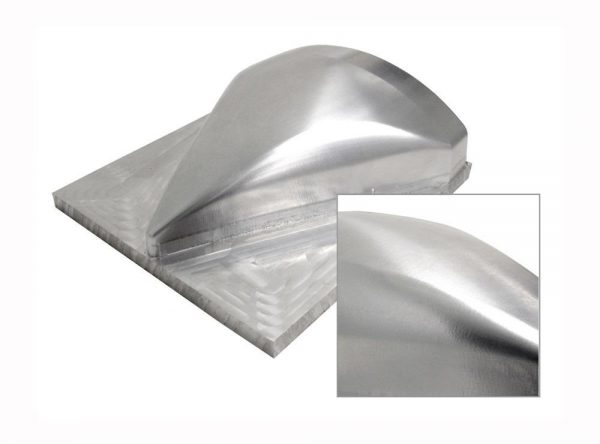

5 axis machining*

Is It Worth It To Get 5 Axis CNC Machining?

The 5-axis machining system offers us the best quality results while improving productivity “timings”, optimizing production at the same time. This system multiplies the available production options, either in terms of dimensions or format of the products or pieces that they want to produce. As we have already said, you can work with more complex parts and even obtain a higher quality finish. In addition, it minimizes the amount of cost and time required in the preparation of spare parts, offering, therefore, better performance of the production if we consider the total time required together with the aesthetic result of the piece. In short, a piece of superior quality that meets the objectives set and improve delivery times.

Advanced Technology In 5-axis CNC Technology

Hurco has a series of features that make 5-sided and 5axis CNC machining more efficient.

Management of the tool center. Eliminates the need to calculate the center of rotation of the machining centers. Instead, you simply use the zero point in the solid as a reference.

Plane change. Calculate other coordinates for each rotary motion after you assign zero-part. The control software requires that you only define the zero-part, and it will calculate the other zero-part points automatically.

- 3- Tool Compensation

Eliminates the need to re-accommodate the diameter of the tool used. For 3-D surfaces, operators eliminate the center of the tool to obtain a better final finish and preserve the life of the tool. This feature allows you to compensate for wear without re-adjustment.

- Linearization Of The Tool Stroke

Eliminates speculation in the part and linear segments in the XYZBC axes or AC movements that use CAM systems, which results in smoother final finishes and smaller programs.

- Tool Vector Input

It allows the control to calculate the angles and positions of the machine and also calculates the angle of the tool when it is inclined and in contact with the surface of the piece. Retraction of the Tool Vector, tells the spindle to retract outside of a hole or box on the tool vector angle, which prevents the tool from breaking and/or damaging the part.

- Shortest Angular Traverse

Take the fastest angular path to reach the desired position.

5 Axis CNC Machining

Thus, we talk about the synergy between precision, quality, profitability, efficiency, and innovation, in this case, around a single axis, the 5 axis CNC machining systems.

Hopefully we have shed some light on how 5 axis CNC technology could be best for you. We work with the latest technology and guarantee the excellent quality of our products and our services. For this reason, after this article, we invite you to visit the different options that are available for you to choose from. You should do your own research on which of the machining systems that are available could better suit your needs for rapid prototyping.

Reference

*Image from on https://www.datron.com