3D Printing Services

SLA and SLS Rapid Printing Services

Prototypes in 24-48 Hours

LT Century provides rapid SLA and SLS 3D printing services internationally creating prototypes in as little as 24-48 hours. 3D printing creates prototypes quickly, allowing you to touch, see, and test your design in physical form. 3D printed prototypes allow moving parts, colorization, and much more.

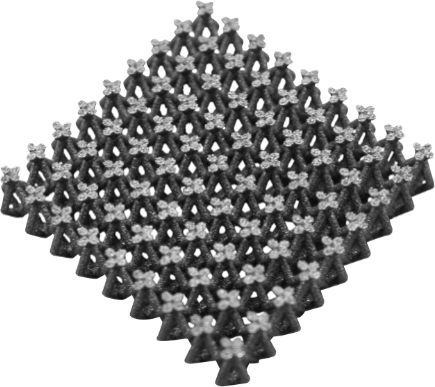

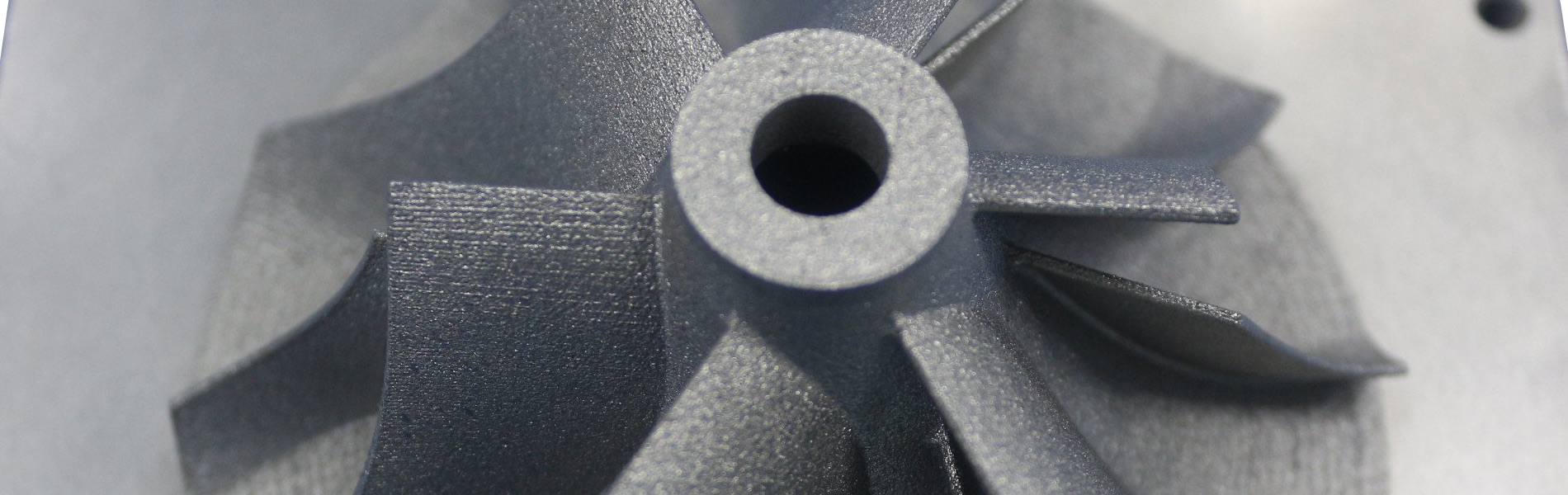

Using your design data, we print 3D prototypes using a wide variety of materials. In both SLA and SLS printing layers of material are continually added until the design has been completed, at which point many different finishing treatments are available to enhance, protect, and highlight your prototype.

Items made using SLA or SLS 3D printing technology may be enhanced with additional texturing, paint, other accents and even additional moving parts or inserts. Place a prototype in your hands fast using 3D printing services by LT Century.

3D Printing Services

We offer 2 options to serve your 3d printing needs: SLA and SLS. Your project needs will be the strongest determining factor which method is best for you.

SLA Printing

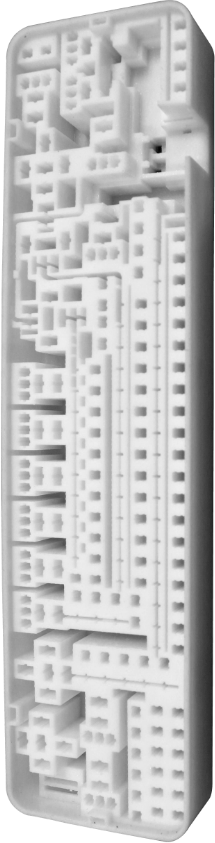

SLA printing is a 3D printing process using layers to create a complete and solid design. Using your CAD data (we can help with that too) your design is created using the material you have selected. Liquified, layered, and cured, materials are continually added until the design is complete, then cured. Prototypes made using the SLA rapid printing process are stationary replicas of your design built to specification.

SLA Printing Process

- Ideas, concepts, and designs are converted to 3D CAD files

- The design is divided into layers, made in succession using liquid resin

- Each layer is traced from liquid resin, creating the design and curing the previous layer

- This process continues until the 3D printed prototype is complete, and excess materials are removed

- The prototype is cured, cleaned, and ready for finishing treatments

Benefits of SLA Printing

- Variety of material and finishing options available

- Precision creation of complicated designs

- Produced in as little as 24 hours

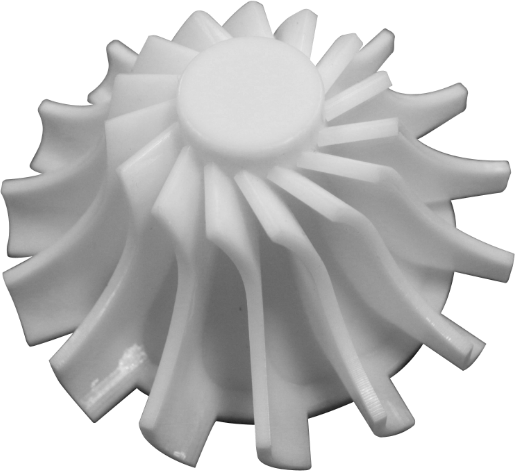

SLS Printing

SLS printing is another form of 3D printing used to create functional prototypes which move and support the attachment or inclusion of additional parts and pieces. The SLS printing process creates layers separate from each other, then fuses them together using laser technology. 3D printed prototypes made using SLS printing can be ready to ship in as little as 24-48 hours.

SLS Rapid Prototyping

- 3D CAD designs are created and used to form materials into layers

- A bottom layer is created to support building the design

- Layers are added, fusing previous together layers with heat

- Designs are cooled, cured, and cleaned

- Finishing treatments may be applied and the prototype is ready to ship

Advantages of SLS Printing

- Variety of materials, colors, and finishes

- Accurate, moveable representations of your concept

- Shipping as fast as 24-48 hours